Developing programmes to reduce greenhouse gas emissions

To combat global climate change, it’s important to reduce the greenhouse gas emissions of feed and food production. Not least because global warming has an enormous impact on agriculture throughout the world. At De Heus, we are committed to implementing programmes that aim to create emission reductions in feed production and food supply chain. Leading these programmes is Stefan van den Bogaard, Group Director Technology & Investments. He tells us about De Heus’s strategies to reduce the company’s global carbon footprint and how De Heus’ local expertise is generating new ideas for sustainable solutions.

Safeguarding future generations

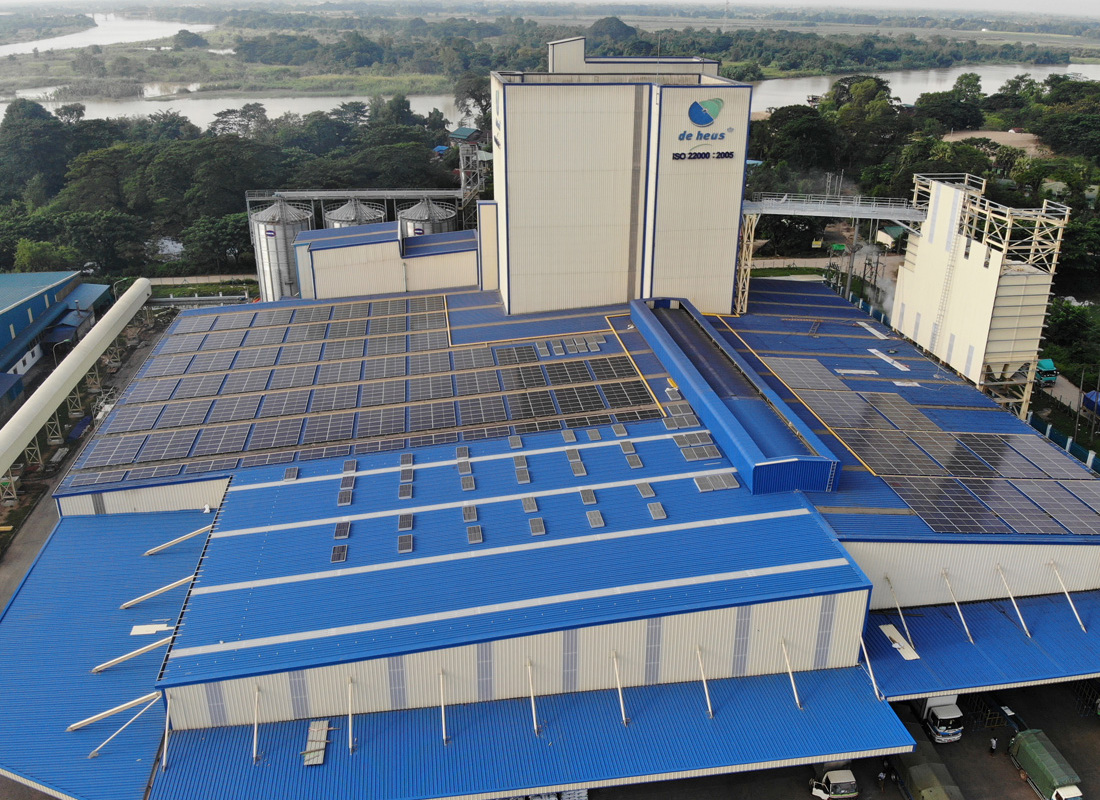

“De Heus has been working to reduce its greenhouse gas emissions since 2018, when we implemented our first solar project in Mandalay, Myanmar” says Stefan. “Now that the 2015 Paris Agreement aims to reach net-zero emissions by 2050, and the EU Corporate Sustainability Reporting Directive will require us to report our greenhouse gas emissions, we’re being more vocal about our reduction initiatives.” But it’s not just legislation that’s driving De Heus to reduce its carbon footprint. “As a family owned-business, we care about future generations and want to minimise the impact on climate change and reduce emissions,” adds Stefan. “It’s in our genes to safeguard the environment and take care of the livelihoods of communities”.

“It’s in our genes to safeguard the environment and take care of the livelihoods of communities.”

Reducing emissions is challenging

Reducing the emissions of primary processes in feed production is challenging and there isn’t a one-size-fits-all solution. “We make mash and pelleted feed,” explains Stefan. “Mash feed just requires electricity, while pelleted and extruded feed needs both steam and electricity.” The company could use electricity alone to produce steam but at the moment this isn’t economically feasible and the capacity of the local energy grid sometimes isn’t sufficient to handle the increased power demand. Solar panels could provide some of the energy required, but there are also limitations as roof space in some countries is limited and we find it important that solar panel locations do not conflict with agricultural land. “We could also use biomass to generate steam instead of using coal or gas but there we run into similar problems,” says Stefan. “There’s plenty of biomass in some countries, but in others it’s unavailable or too expensive. We already have several feed mills running on rice husk for example, this is a waste product of the rice milling industry that would normally be burnt or go to waste.”

Avoid, reduce or compensate

Given these challenges, how does De Heus approach its emission reduction programmes? “We use a strategy we call ARC: Avoid, Reduce or Compensate,” says Stefan. “In terms of reducing fossil energy sources, we’ve invested in a number of alternative energy sources such as biomass, and solar energy.” The company already has several of its own solar energy systems in various countries including Spain, Portugal, Cambodia and Myanmar.

More recently, De Heus signed a memorandum of understanding for a solar energy project covering 30 facilities owned by De Heus and Bel Ga in Vietnam. It’s the largest project of its kind in the country and since it’s expected to generate more than 28 million kWh of clean energy it will prevent more than 22,500 tons of carbon emissions each year. This is comparable to the annual carbon dioxide absorption capacity of 1 million mature trees, or offsetting emissions by 5,000 cars per year. “The best place to invest in solar power is near the Equator where the sun shines the brightest,” Stefan continues. “But we also have solar systems in three factories and our swine research farm in the Netherlands. These solar systems contribute to greenhouse gas reductions, but as I said they have their limitations so we continue to explore other options.”

Combined heat and power

A second alternative source is co-generation, also known as combined heat and power (CHP), which is the simultaneous production of electricity, steam and useful heat from a single fuel source. “At our factories in Eastern Europe, we mostly use gas to produce heat and steam for pelleting,” says Stefan. “Through co-generation, some of the steam is used to generate electricity. The CHP efficiency is much higher than having a separate boiler to make steam and drawing electricity from the local grid, which saves a significant amount of CO2 emissions.” At De Heus’ feed mill in Mieścisko, Poland, heat produced by co-generation is also used to heat a tank room where oils and other ingredients need to be kept warm.

Biomass

Biomass is another renewable energy source related to reduction. A striking example of this can be seen at De Heus’ aqua feed factory in Vinh Long in the Mekong Delta in Vietnam. “Aqua feed production requires a lot of steam,” says Stefan. “At the Vietnam factory, we’ve invested in special boilers that are fuelled by rice husk rather than conventional fuels such as coal.” This use of agricultural waste is linked to De Heus’ aim to use more residual flows in its feed production. “We plan to use more biomass but only if it’s not been grown specifically for energy production,” continues Stefan. “For example, we’re planning a new factory in Uganda where there’s a huge sugar industry, and we’re looking at whether we can use bagasse, a dry fibrous material left over from sugarcane processing, or rice husk to generate power.” Another country with a great deal of potential is South Africa. The nation is highly dependent on coal for electricity and steam generation but it’s facing issues with security of supply. “We’re looking into options for steam generation that could be replaced with the abundant supplies of biomass that are available in some regions of the country,” says Stefan.

Innovative avoidance methods

As for the avoidance pillar of its ARC strategy, De Heus is always looking for new ways to increase efficiencies in the company’s primary processes. Innovative examples of this include using residual heat from aqua feed production for heating and power generation, and the use of fewer conveyor belts in favour of bucket systems driven by smaller, more energy-efficient motors. “We’re also working with animal nutritionists and product managers to see if we can partly switch animals from pellet feed to mash feed while achieving the same results,” says Stefan. “This would reduce the amount of energy used in pellet production, however we can’t do without pelleted feed entirely for reasons related to animal husbandry, logistics and contamination.”

Compensating for greenhouse gas emissions

“If we can’t avoid greenhouse gas emissions or reduce them, we have to compensate for them, which is the third pillar of our ARC strategy,” says Stefan. “This involves measures like investing in our customers to help them reduce emissions or making our incoming raw materials more sustainable.” Compensation can also involve De Heus investing in solar or wind farms outside its own factories. “Solar panels alone won’t help us reach our emission reduction targets,” Stefan admits. “Using biomass and optimising our primary processes can help, but if we can’t do it on our own, we can invest in external, commercial renewable energy sources.” Another area where compensation can have a big impact is the emissions generated by feed transportation. “Trucks make a substantial contribution to greenhouse gas emissions and it’s hard to change that by ourselves,” says Stefan. “So we have a responsibility to monitor developments in hydrogen and electric vehicles for example, and maintain discussion about those options with the transport sector.”

Generating ideas locally

Although Stefan and his team are driving these programmes, a lot of ideas for emissions reduction are coming from the company’s local business units. “That’s typically De Heus,” says Stefan. “We’re a global, entrepreneurial company and we use ideas from different countries.” A member of Stefan’s team is responsible for fielding these ideas, developing them further and growing the company’s expertise. “We have to reduce emissions in a coordinated way and seize the low-hanging fruit,” he continues. “For example, in several African countries, a lot of energy is hydroelectric, generated by moving water. In Uganda, it’s generated from Lake Victoria. We’re looking at the possibility of using it in our new factory there. It’s part of feasibility study into making the facility net-zero from the start.” In Vietnam, De Heus is also in the early stages of research into the possibility of generating electricity from smart grids with a combination of solar energy and battery storage.

“We have to reduce emissions in a coordinated way and seize the low-hanging fruit.”

Personal responsibility

While De Heus as a company addresses sustainability on a large scale, it also wants to inspire employees to take responsibility for the environment on a personal level. In the same way that the company wants to reduce emissions from operational processes, people can also make changes in their own immediate surroundings, for example by carpooling.

Greenhouse gases and employer branding

Beyond the environmental benefits of reducing greenhouse gas emissions, all these initiatives help make De Heus an attractive employer for current and future generations. “When we opened our factory in Myanmar with its solar panels and rice husk boiler, one employee told me he was proud to work for De Heus because we care about the environment,” explains Stefan. “When interviewing for a job, my generation asked: Do you do anything about corporate social responsibility? Young people today ask: What are you doing about corporate social responsibility? Our license to operate is that we take care of the future.”